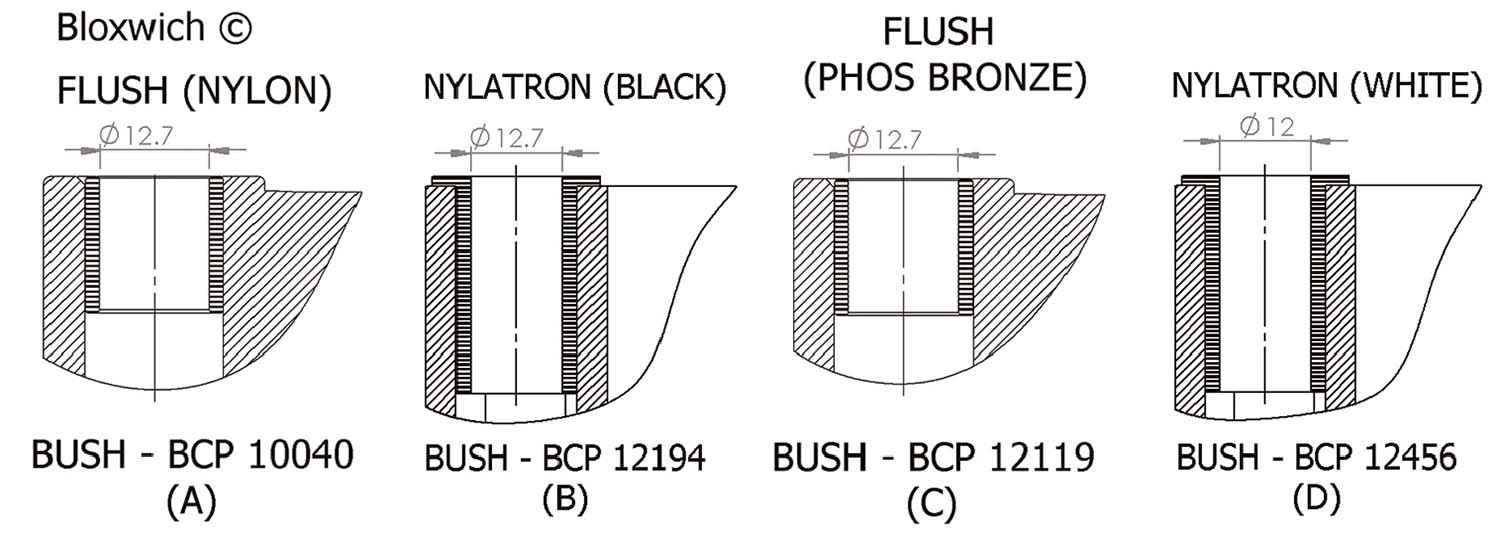

Hinge ProductsHinges & Brackets The choice of hinges, brackets and associated parts depends on end frame and door design and the test requirements for end wall and racking loads. We will be pleased to give detailed advice, but the following points should be considered: -Forged steel door hinges can usually only be welded to the doors -Finish, self colour, zinc plated or galvanised are available* -Nylon (A), (B) & (D) or phosphor bronze (C) bushes are available* -Bolt-on brackets and hinges can be fitted after final painting -If repairs are necessary, removal or replacement of bolt-on brackets and hinges is simple -Flat back design forged steel door hinges are not recommended for use on offshore container main doors -Customer logos are available subject to minimum order quantities*. No logo (O) is standard -Grease nipples ( N or NSS) can only be fitted to our range of forged hinges (see illustration for fitting positions). Other positions available on request -Bloxwich recommend Ø12.7 pins or 1/2” bolts are used for Ø12.7 bushes, however if increased clearance is required Ø12 pins or M12 bolts can be fitted* *Selected hinges only #Subject to quantity and lead time |

Bush Options |

| For option (C) Bloxwich fit Oilite® sintered bronze bushes. Oilite® is the undisputed market leader in self-lubricating bearings and the properties of the standard Oilite® oil retaining tin bronze give a good balance between strength, wear resistance, conformability and durability in operation. They are ideal in a wide variety of applications where "self-lubricating" properties are required over a long period of time. |

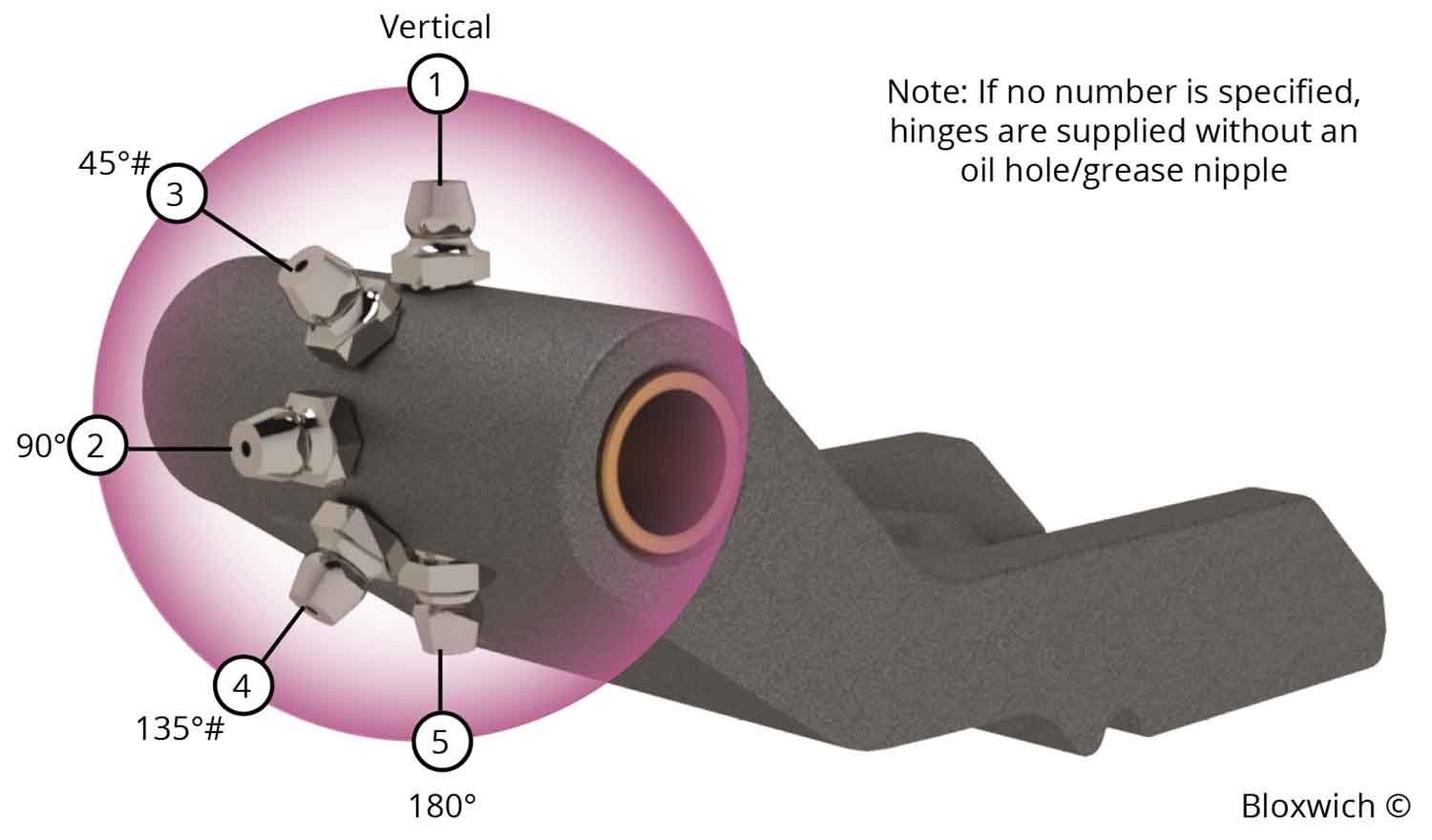

Standard Forged Hinge Oil Hole/Grease Nipple Positions |

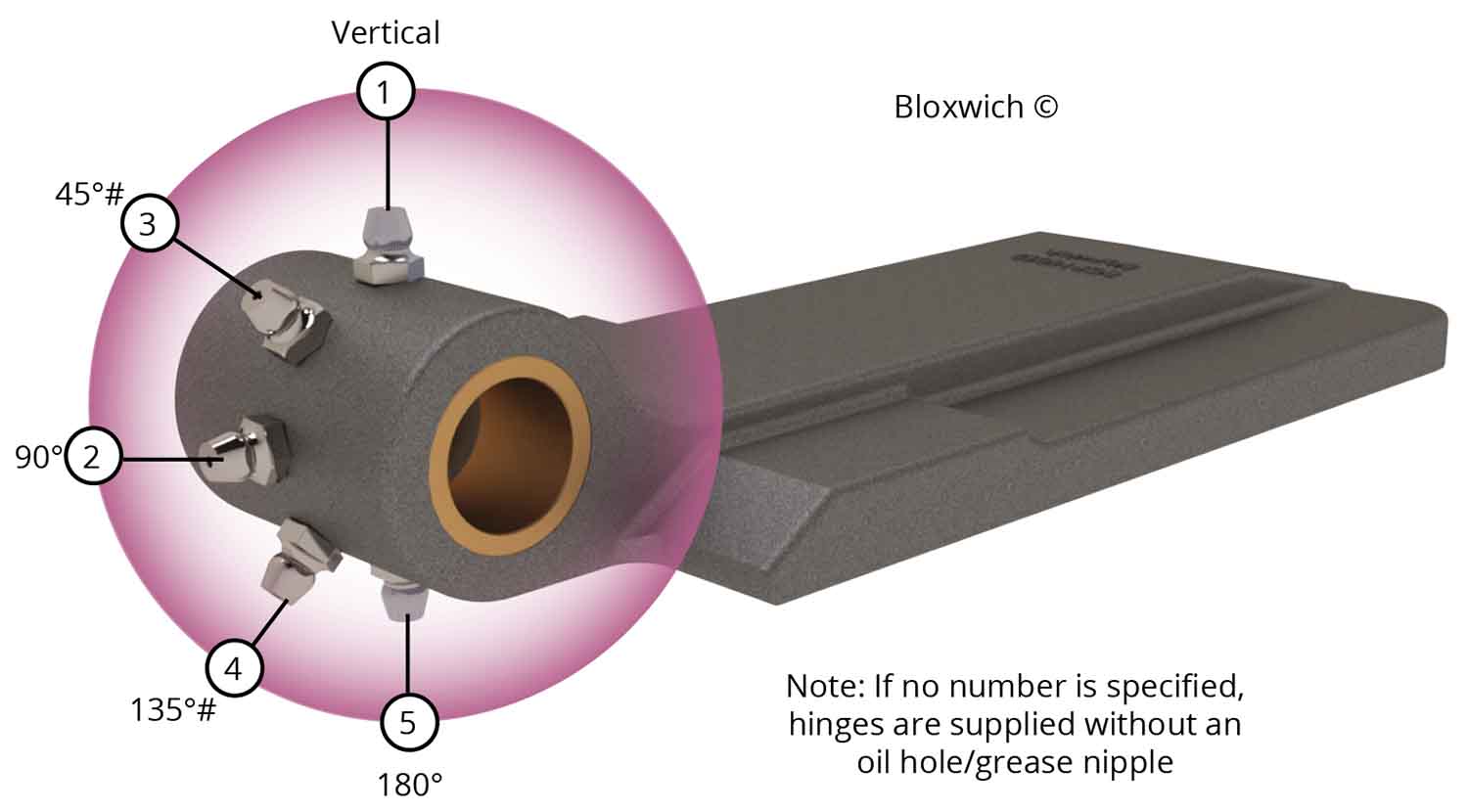

Heavy Duty Forged Hinge Oil Hole/Grease Nipple Positions |

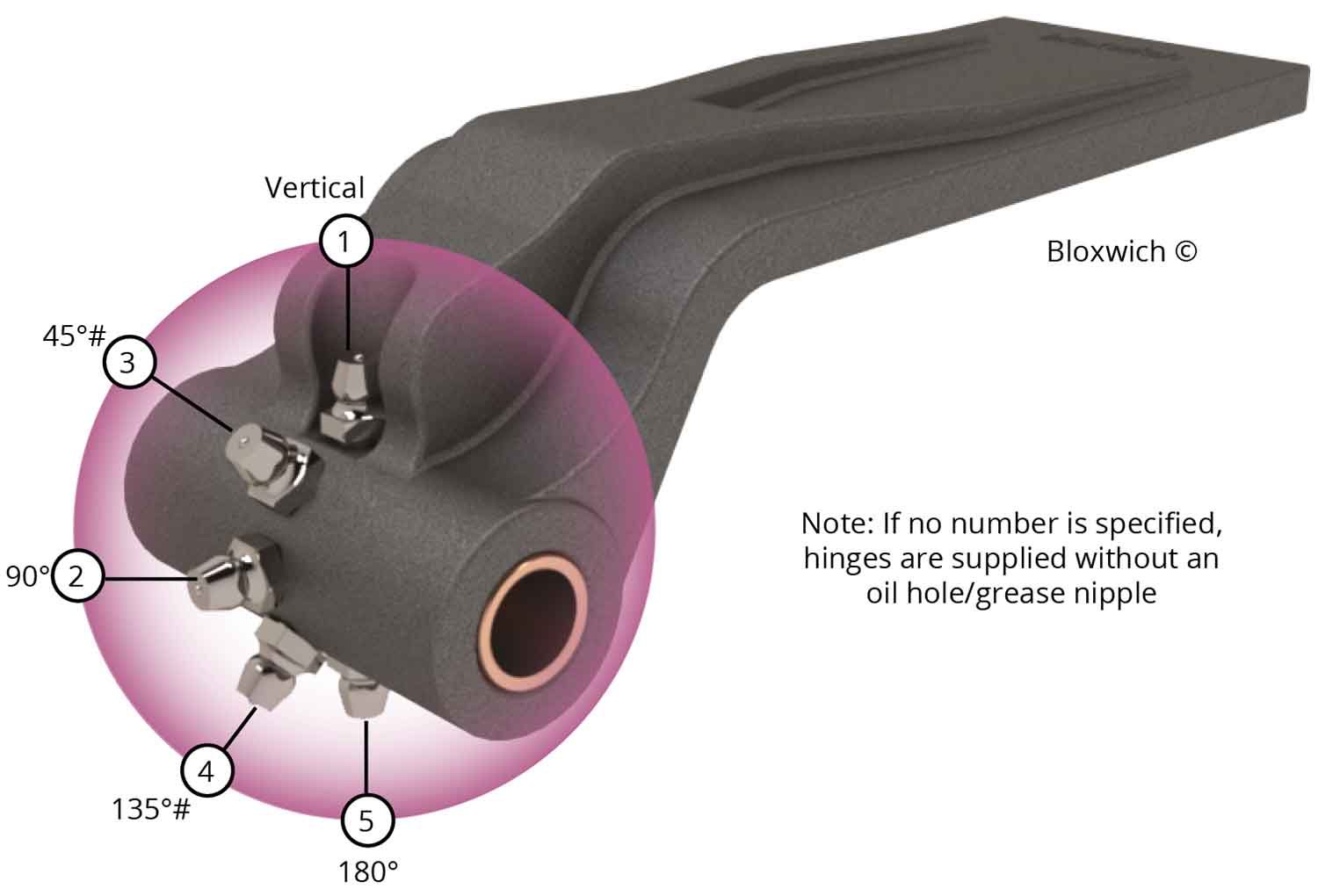

Reverse Forged Hinge Oil Hole/Grease Nipple Positions |

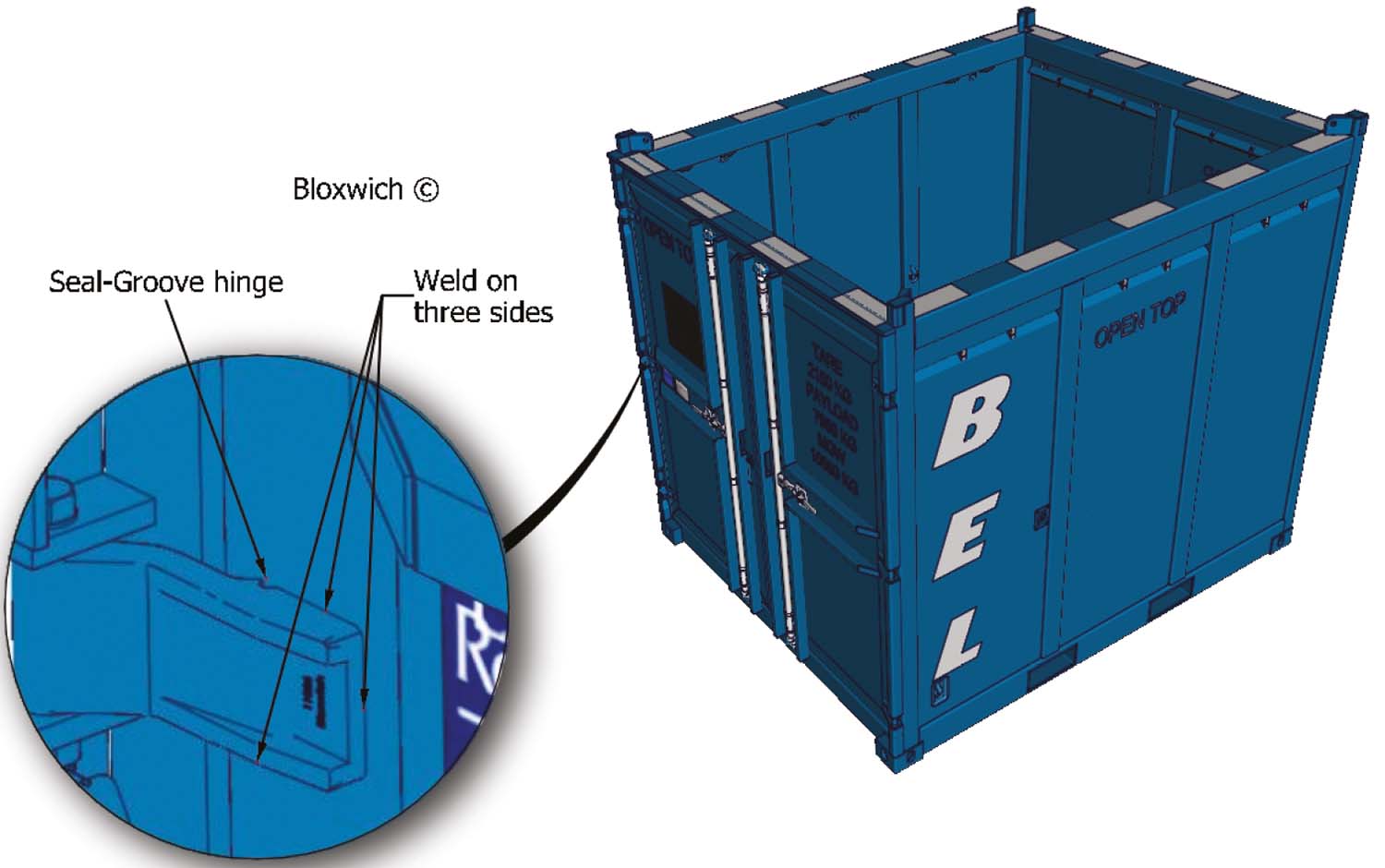

Seal-Groove Hinges |

| Depending upon the design it can be impossible to weld the area between the back of the hinge and the face of the door if using J seals. Bloxwich "Seal-Groove" hinges: -Allows sealant to be applied forming a barrier across unwelded part of hinge. -Prevents corrosion by stopping ingress of water behind hinge. -Sealant easily applied by conventional sealant gun. -Prevents rust streaks (as found with conventional hinges ) from forming on doors. -Seal-groove provides visual proof that the hinge has been sealed over total width. |